Quarry Crusher

A quarry is a type of strip mine from which rock or minerals are extracted. Quarries are generally used for extracting building materials, such as dimension stone, construction aggregate, riprap, sand, and gravel. Quarry crusher is born with innovative significance. It is newly designed and improved by our experts on basis of their more than 20 years' crusher manufacturing and design experience. The unique design concept makes this series quarry crusher plant price achieve perfect combination between crushing efficiency and operating cost. Meanwhile, it has a wide range of application, particularly is suitable for crushing hard rock, such as basalt, river pebbles.

Application of Quarry Crusher

Among the many varieties quarry crusher, jaw crusher and impact crusher, cone crusher is the most traditional crusher for crushing basalt, granite and other materials hardness is relatively large, the material sheet material disadvantage is relatively ;large output; However, for large production materials such as limestone and other brittle materials overkill.With the development of machinery industry, emerging out of the new model, the material more targeted, more broken than to better meet customer needs.

Quarry crusher is widely used for medium crushing various ores and bulk materials in mining, smelting, building materials, highway, railway, water, chemical industry and other industries. The crushed materials are of a compressive strength less than 320MPa. Jaw crusher has the characteristics of big crushing ratio, uniform finished product size, simple structure, reliable work, convenient repair and low operating costs.

Working principle of Quarry Crusher

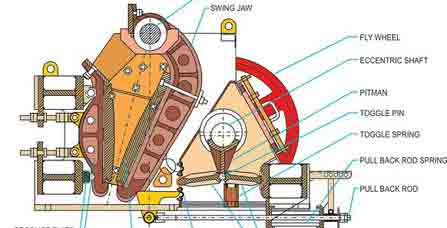

The motor transmits power through belt and belt pulley, drives the swing jaw surround the eccentric shaft do periodic motion. The angle between toggle plate and swing jaw increases when swing jaw moves up., which makes the moving jaw get closes to the fixed jaw.At the same time the material is squeezed, rubbing, grinding and other multiple broken. The angle of Jaw Crusher between toggle plate and swing jaw decreases when swing jaw moves down, the moving jaw of Jaw Crusher moves away from fixed jaw by the pulling of rod and spring, the products after crushing will be discharged from the outlet of Jaw Crusher.

Features of Quarry Crusher

- Many cavity to crush, suitable for crushing hard rock.

- Reasonable design of leveling plate making charge finer and cubic without interior cracks.

- Low and big feed opening makes the production line easy to arrange and increase the size of feeding material.

- Use the hydraulic to open, easy to maintain and change wear-parts.

- New anti-abrasive material makes longer service life of impact bar, impact plate and liner.

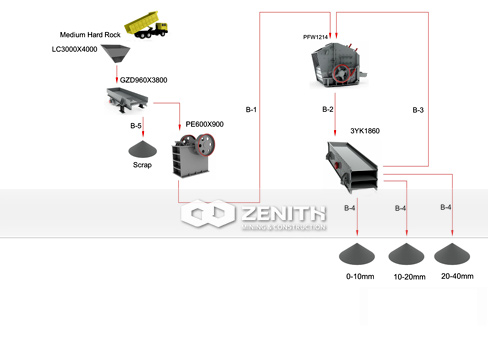

Quarry crusher machine for sand making line

In the process of sand making production line, raw materials are conveyed to the jaw crusher for a coarse crushing by the belt conveyor; after the rough crushing, the materials are conveyed into a fine jaw crusher for a further crushing, then the fine crushed materials are conveyed into the vibrating screen for a separation which classified the materials into two kinds of stone, one part that meet the size of feeding mechanism of sand gravel base sand will feed into the sand making machine, another part will feed back again into the fine jaw crusher for a third crushing, the size of fineness can be adjusted according to customer demand. Fine jaw crusher are the improved simple pendulum or compound pendulum quarry crusher plant price, which applys a plurality of the dynamic jaws and a plurality of eccentric shaft structures, which will reduce the loads of the machine when the jaw crusher running. And it is easy to start, smooth to run and with low energy consumption.