Vertical Roller Mill

Mobile Crushing a kind of high efficiency crushing equipment, driven by their own way, the technology is advanced, the function is all ready.Excellent location mobile mobility and job site adaptability, no stationary crushing plant in place before the need of all kinds of preparation, it can be finished in a short time location adjustment, at any time.This reduces the material processing operations, and convenient all the coordination of auxiliary machinery.Through the wireless remote control, can easily take crusher on the trailer, and will ship it to work.

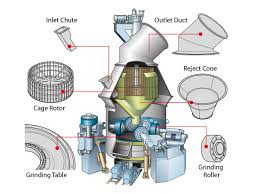

Structure of Vertical Roller Mill

The main structure of the separator vertical mill , roller device , disc device , pressing device , part of the reducer, motor , housing and so on. Separator is an important component determines the thickness of the mill product , which consists of adjustable speed drives , rotor, guide blades, housing , meals, blanking the cone , outlet , etc., is a highly efficient , energy-saving , efficient separator device .LUM ultrafine vertical roller mill is the main component of the material for rolling mill . It was installed in the mill bent arm , under the action of external forces , the material is pressed against the disc , the disc in the drive , the roller will rotate , allowing the material to be compacted and crushed.

Vertical Roller Mill Features

- Lower energy consumption for producing the same amount of materials.

- High fineness: our roller mills are equipped with high precision classification system, which help guarantee high product fineness. And the particle size distribution of finished product is adjustable.

- This impact mill is suitable for grinding materials with wide range of size: 325mesh-2,500mesh are all possible.

- Wear-resistance: the wearing parts for our roller mills are made of wear-resistance composite materials, which feature longer service life.

- Intelligent operation control guarantees a simple operation and stable performance.

- Environmentally friendly: the main machine adopted vibration-reduction and noise-cancellation technology; and negative pressure production process effectively avoided dust pollution.